CLOSE X

Shaft

- Hardened steel 2¼”” (57 mm) shaft is engineered for long life expectancy at high tensions.

CLOSE X

Running Cable

- Galvanized steel core cable is available in 5/16″ (8 mm) and 3/8″ (9.5 mm).

- Fibre core cable is available in 5/16″ (8 mm) and 3/8″ (9.5 mm).

- Material specifications available upon request.

- Speak with a Konex representative to decide which type of cable to go with.

CLOSE X

Control Panel Enclosure

- A properly vented enclosure protects your control panel and the wired or wireless remotes from the weather.

- Both gull wing doors are separately keyed/ lockable to prevent unauthorized access.

CLOSE X

Carrier

- Brushed stainless steel frame for maximum life expectancy and aesthetic appeal.

- Exceptionally durable synthetic pulley and rollers

- Large 6” (150 mm) top pulley has low RPM’s to reduce noise and wear.

- Crosby™ hardware.

CLOSE X

Sensors

- Inductive proximity sensors have no moving parts.

- Can operate in all weather conditions including being covered in a layer of ice.

- Plug n’ play connections make it easy to replace if damaged.

CLOSE X

Wired Remote

- The wired remote comes with the largest potentiometer (speed dial) available.

- Dead man push buttons for forward and reverse.

- Illuminated push button for homing/ error acknowledgement.

- Wire length is 33 feet (10 m). Request for extra.

CLOSE X

Operating System

- Set turn points with the wired remote in minutes – no computer or iPad required

- 3 pre-programmed run modes that can be activated on-the-fly by a key switch on the control panel.

- Semi-automatic and full-automatic operating modes.

- Manual mode key switch to bypass software in case of emergency.

- Easter egg functionality on the wired remote for hidden features.

CLOSE X

Power Supply

- Can accommodate all power sources;

- 1 phase 200V – 240V (household power)

- 3 phase 200V – 240V

- 3 phase 380V – 500V

- 3 phase 525V – 600V

CLOSE X

Control Panel

- CSA and CE certified.

- Can accommodate all power sources including single phase 220 – 240V (household power); 3 phase 220 – 240V; 3 phase 460-480V; 3 phase 575-600V; 50 and 60 Hz

- Cold weather package available.

- Plug and play connections.

CLOSE X

Tension Measuring

- Digital readout of the cable tension on the control panel.

- A built in load cell measures and displays the tension of the cable in real time.

- Observe the amount of tension a rider can apply to the cable.

- Observe the effect that thermal expansion has on the cable and ride throughout the day.

- Set the appropriate tension to accommodate larger loads when tubing.

- Electronic shutdown prevents system operation if over tensioned. Tension limit is manually set by a tamper proof hydraulic relief valves so this is an extra safety measure.

CLOSE X

Hydraulic Tension Bar

- Effortlessly adjust the cable tension up to 15,000 lb (67kN).

- Tensioning can be completed in minutes – simply open the two hydraulic valves and activate the hydraulic pump with an eye on the tension readout on the control panel.

- Relief valves and tamper proof ports ensure slow and safe movement of the motor tower.

- This rigid tension bar creates a free standing tower independent of the running cable

CLOSE X

Hydraulic Power Pack

- The hydraulic pump is powered by a 12V deep cycle battery.

- The pump, battery and ball valves are in a lockable steel enclosure.

- Tamper proof relief valves ensure that an operator cannot over tension the hydraulic tension bar.

- Stainless steel hard line hydraulic tubing.

- Uses biodegradable hydraulic fluids that are free of heavy metals, non-toxic, and recyclable.

CLOSE X

Safety Harness Anchor Points

- Attach your fall protection equipment on two 5,000 lb (2,270 kg) safety certified D-rings.

- Work comfortably on top of the tower with the peace of mind that you are safe and secure.

CLOSE X

Micro Adjustment

- Pivot the drive and deflection pulley frames on the 1½” vertical pins to align and reduce pulley liner wear.

CLOSE X

Hinged Base

- Heavy duty 1 ½” hinge pins allow tower to smoothly pivot forward.

CLOSE X

Detachable Ladder

- Detachable lower section and lockable ladder guard prevents unauthorized access.

- Perforated anti-slip rungs increase grip to maximize safety.

- Fall arrest equipment anchor point.

CLOSE X

Foundation

- Secure the tower to concrete piles, concrete blocks or screw pile foundation.

- Foundation plans are available on the resources page and can be taken to a local engineer for approval.

- Concrete piles use less material than concrete blocks because they rely on the earth friction and not just sheer weight.

- Screw pile foundations and anchors allow the structure to be considered temporary for permits. Screw piles are excellent in cold weather climates due to resistance to frost heaves.

CLOSE X

Stainless Steel

- This option is recommended for saltwater applications.

- Visually appealing for distinguished buyers.

CLOSE X

Conduit Rings

- Neatly guides the power and instrumentation wires down either side of the motor tower and out of sight.

- Both wires are secured above by strain reliefs.

CLOSE X

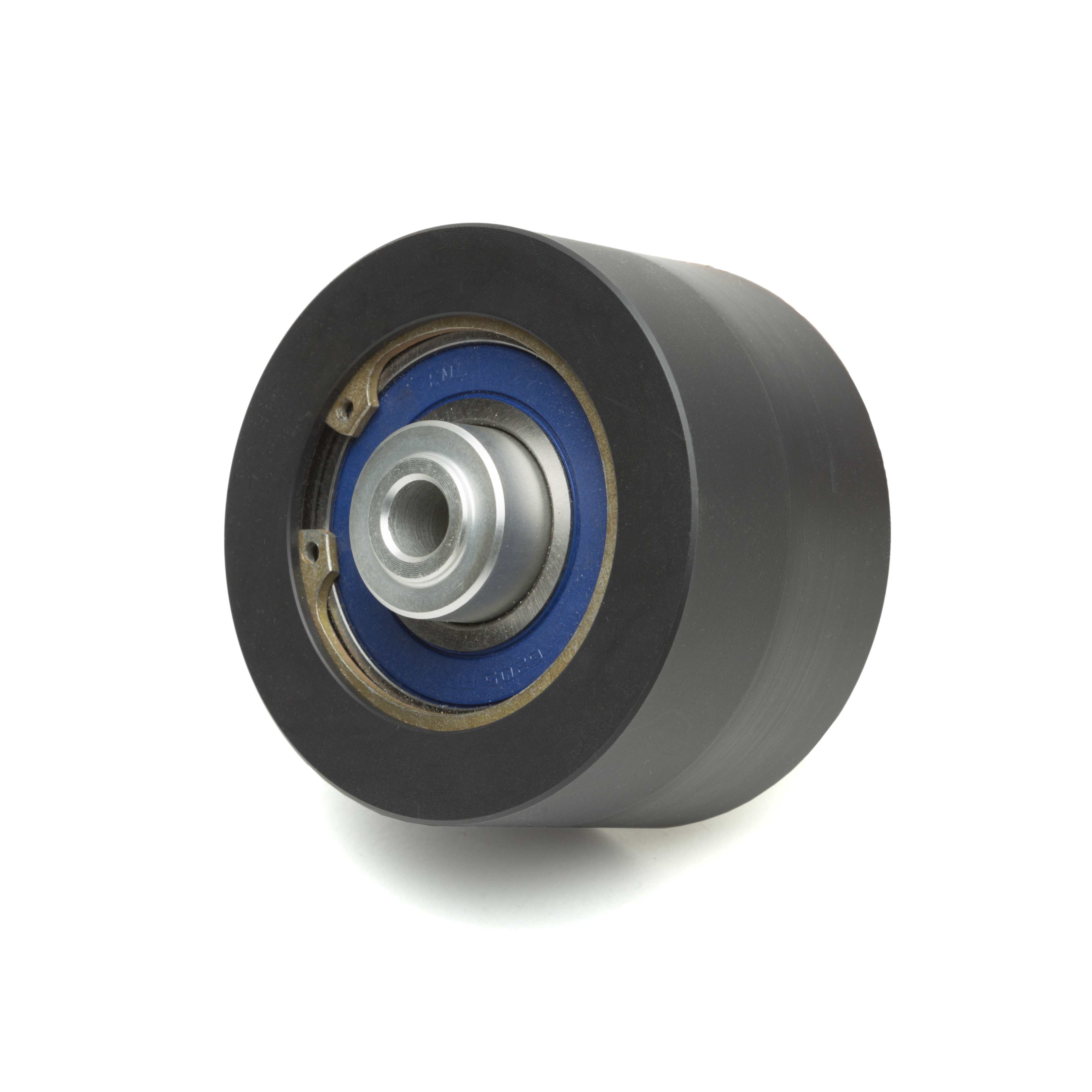

Bearings

- Heavy duty 2” (50 mm) SKF roller bearings bearings rated for long life expectancy at high tensions.

- Sealed bearings prevent contaminants from entering and reduces greasing intervals.

- Tapered locking mechanism firmly secures bearing to shaft to prevent slippage in this violent application

CLOSE X

Hood / Work Platform

- When closed there is reduced motor noise and extra protection of the mechanical system from the weather.

- When unlatched the hoods drop down to become a safe work platform.

- Comfortably perform maintenance at chest level.

- Enjoy the view with another technician on the opposite work platform.

- Anti-slip raised edges that also prevents bolts and tools from rolling off.

- Engineered for 700 lbs (317 kg) point loaded at the edge of the platform.

- Seadek is available for extra comfort and style.

CLOSE X

Tower

- Stress tested with advanced CAD design software.

- Maximum functionality and detail is laser cut into every part.

- Multiple serial numbers stamped into the steel for unit identification.

CLOSE X

3 Piece Pulley Inserts

- Our patented 3-piece pulley design makes it possible to replace worn pulley inserts without removing the cable.

- Exceptionally durable synthetic inserts increase life expectancy and reduce maintenance.

CLOSE X

Motor

- Comes standard with 5 HP (3.7 kW) motor and right angle gearbox made to last in this demanding application.

- This robust gearbox has 45% more surface contact between gears and a very high service factor.

- Direct drive design provides smooth transmission of torque and acceleration with a high level of positional precision.

- For longer cable spans and heavier loads upgrade to a 7.5 HP (5.6 kW) motor or even a 10 HP (7.5 kW) motor

- Contact a Konex representative for advice on which motor size is suitable for your site.

CLOSE X

Colours

- Zinc base primer comes standard on all powder coated towers for extra corrosion protection.

- 300 colour options / 10 accent areas available to make your towers stand out or camouflage them into the surrounding environment.

- Customize, save and share your favourite tower designs online in the Design Studio.

- Contact Konex for special requests like chrome or sparkle undercoat with transparent candy overcoats.

Numerous features patent-pending.

- Reset

-

Quick

Quick

-

Safe

Safe

-

Quiet

Quiet

-

High Performance

High Performance

-

Durable

Durable